Ampxell Lithium Iron Phosphate Battery

The LiFePO4 (Lithium Iron Phosphate) battery, also called the LFP battery, is a type of rechargeable battery. It is the safest Lithium battery type currently available on the market today. It is made to be a small size and light in weight, and it has a high energy density. It's cycle life can reach thousands of cycles. AMPXELL's LiFePO4 batteries offer high-powered cell performance that is compatible with many Lithium-ion applications and able to delivery more power and longer life.

|

No |

FB8086185EF -12Ah |

|||

|

1 |

Basic performance |

Specification size |

Thickness * Width * Length (mm) |

8.2*86.0*183.0 |

|

2 |

Weight (g) |

259.6 |

||

|

3 |

Internal resistance to ACR (m Ω) |

0.95 |

||

|

4 |

1C |

capacity (mAh) |

11891 |

|

|

5 |

Median voltage (V) |

3.224 |

||

|

6 |

Electric performance |

3C |

Median voltage (V) |

3.122 |

|

7 |

The 3C/1C capacity retention rate is (%) |

95.1 |

||

|

8 |

5C |

Median voltage (V) |

2.991 |

|

|

9 |

The 5C/1C capacity retention rate is (%) |

91.4 |

||

|

10 |

Normal temperature @1Y |

The 0.5C capacity retention rate is (%) |

90.12 |

|

|

11 |

0.5C capacity recovery rate (%) |

94.03 |

||

|

12 |

Expansion rate (%) |

2.59 |

||

|

13 |

65°C@7d |

The 0.5C capacity retention rate is (%) |

95.15 |

|

|

14 |

0.5C capacity recovery rate (%) |

98.06 |

||

|

15 |

Expansion rate (%) |

4.48 |

||

|

16 |

80°C@24h |

The 0.5C capacity retention rate is (%) |

98.81 |

|

|

17 |

0.5C capacity recovery rate (%) |

96.96 |

||

|

18 |

Expansion rate (%) |

2.87 |

||

|

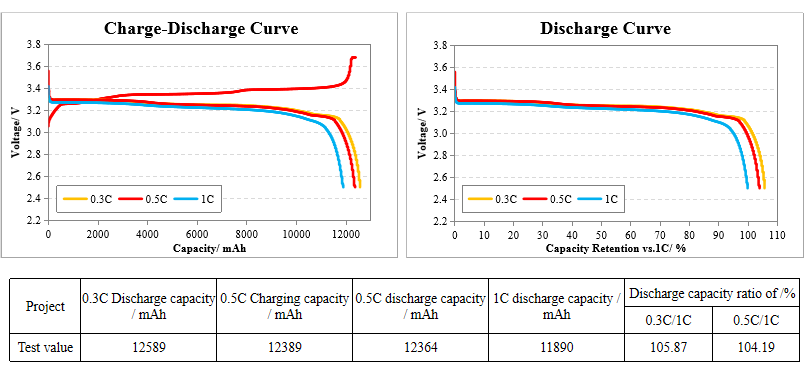

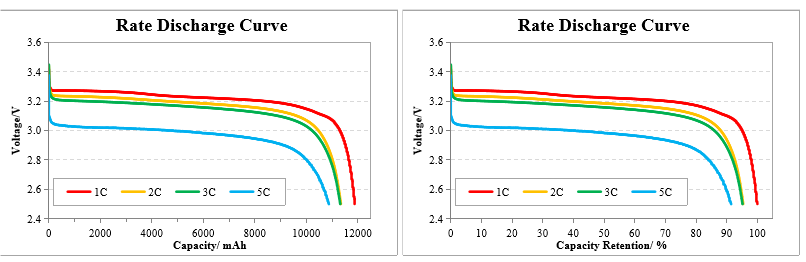

Project |

Discharge capacity / mAh |

Capacity retention rate is vs.1C/% |

Median voltage / V |

|

1C |

11891 |

100.0 |

3.224 |

|

2C |

11340 |

95.3 |

3.188 |

|

3C |

11312 |

95.1 |

3.122 |

|

5C |

10873 |

91.4 |

2.991 |

|

Normal |

Before constant temperature storage |

After constant temperature storage |

Calculate |

||||||||

|

Core |

Internal |

capacity |

Core |

Internal |

First release |

Cycle |

Expansion |

Internal |

Capacity |

Capacity |

|

|

8.19 |

0.94 |

12358 |

8.40 |

0.99 |

11137 |

11620 |

2.59 |

5.75 |

90.12 |

94.03 |

|

|

65°C |

Before high temperature storage |

After high temperature storage |

Calculate |

||||||||

|

Core |

Internal |

capacity |

Core |

Internal |

First release |

Cycle |

Expansion |

Internal |

Capacity |

Capacity |

|

|

8.15 |

0.92 |

12346 |

8.52 |

0.96 |

11747 |

12106 |

4.48 |

4.69 |

95.15 |

98.06 |

|

|

80°C |

Before high temperature storage |

After high temperature storage |

Calculate |

||||||||

|

Core |

Internal |

capacity |

Core |

Internal |

First release |

Cycle |

Expansion |

Internal |

Capacity |

Capacity |

|

|

8.17 |

0.97 |

12346 |

8.40 |

1.04 |

11971 |

12199 |

2.87 |

7.02 |

96.96 |

98.81 |

|

|

No |

FB4544105HF -1.6Ah |

|||

|

1 |

Basic performance |

Specification size |

Thickness * Width * Length (mm) |

4.5*43.5*106.0 |

|

2 |

Weight (g) |

39.7 |

||

|

3 |

Internal resistance to ACR (m Ω) |

3.0 |

||

|

4 |

1C |

capacity (mAh) |

1650.1 |

|

|

5 |

Median voltage (V) |

3.216 |

||

|

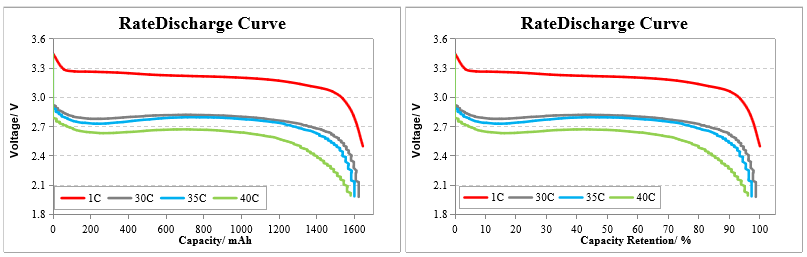

6 |

Electric performance |

30C |

Median voltage (V) |

2.819 |

|

7 |

The 30C/1C capacity retention rate is (%) |

98.6 |

||

|

8 |

35C |

Median voltage (V) |

2.796 |

|

|

9 |

The 35C/1C capacity retention rate is (%) |

97.2 |

||

|

10 |

40C |

Median voltage (V) |

2.668 |

|

|

11 |

The 40C/1C capacity retention rate is (%) |

96.0 |

||

|

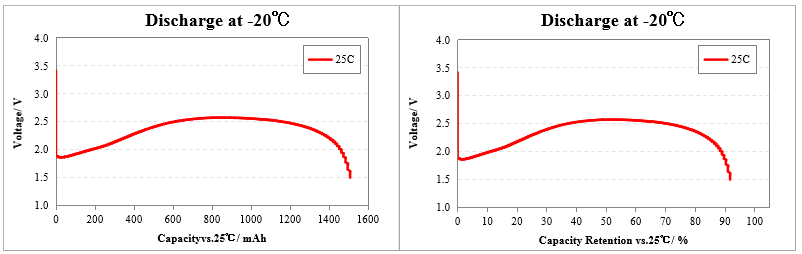

12 |

Low temperature discharge of vs room temperature |

-20°C&25C (%) |

91.6 |

|

|

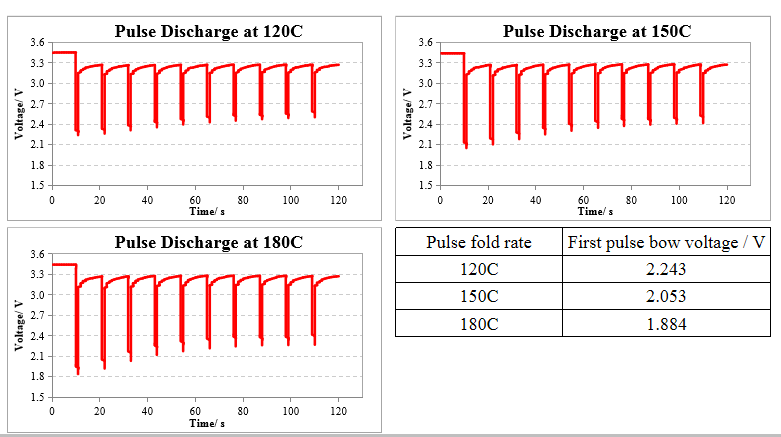

13 |

Pulsed bow voltage @1s |

120C(V ) |

2.243 |

|

|

14 |

150C(V) |

2.053 |

||

|

15 |

180C(V ) |

1.884 |

||

|

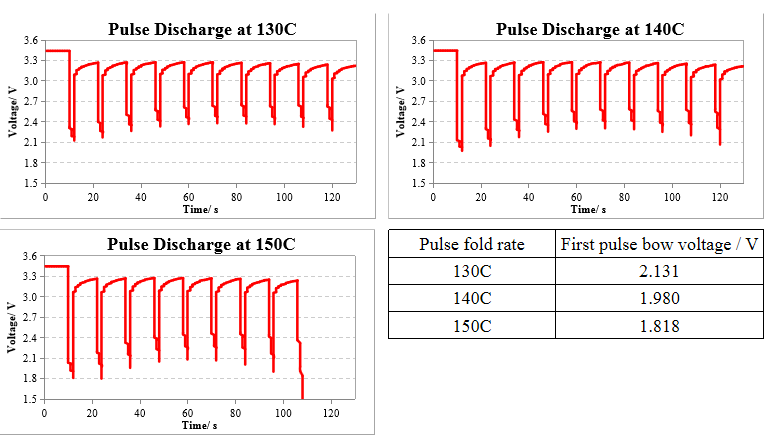

16 |

Pulsed bow voltage @2s |

130C(V ) |

2.131 |

|

|

17 |

140C(V) |

1.980 |

||

|

18 |

150C(V) |

1.818 |

||

|

19 |

Normal temperature @1Y |

The 0.5C capacity retention rate is (%) |

89.97 |

|

|

20 |

0.5C capacity recovery rate (%) |

92.01 |

||

|

21 |

Expansion rate (%) |

2.63 |

||

|

22 |

65°C@7d |

The 0.5C capacity retention rate is (%) |

94.35 |

|

|

23 |

0.5C capacity recovery rate (%) |

97.58 |

||

|

24 |

Expansion rate (%) |

4.59 |

||

|

25 |

80°C@24h |

The 0.5C capacity retention rate is (%) |

96.56 |

|

|

26 |

0.5C capacity recovery rate (%) |

97.92 |

||

|

27 |

Expansion rate (%) |

2.91 |

||

|

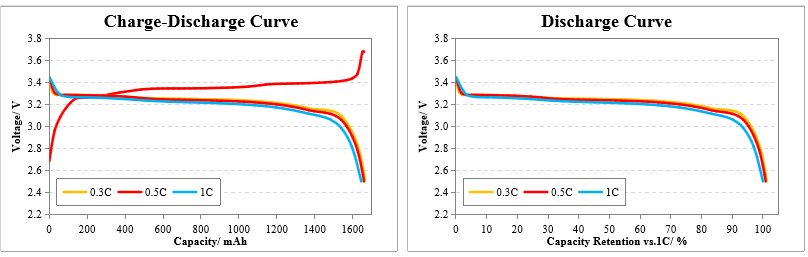

Project |

0.3C Discharge |

0.5C Charging |

0.5C discharge |

1C discharge |

Discharge |

|

|

0.3C/1C |

0.5C/1C |

|||||

|

Test value |

1664 |

1660 |

1659 |

1645 |

101.15 |

100.85 |

|

Project |

Discharge capacity / mAh |

Capacity retention rate is vs.1C/% |

Median voltage / V |

|

1C |

1645 |

100.0 |

3.216 |

|

30C |

1623 |

98.6 |

2.819 |

|

35C |

1600 |

97.2 |

2.796 |

|

40C |

1580 |

96.0 |

2.688 |

|

Project |

Normal temperature |

-20 °C Discharge Capacity |

-20 °C discharge |

-20 °C for discharge |

-20 °C / room temperature |

|

Test value |

1645 |

1508 |

1.857 |

2.560 |

91.6 |

3.5.1 pulse discharge for 1s performance

3.5.2 pulse discharge for 2s performance

Test method: 0.5C constant current pressure to 3.68V, cut-off current 0.05C; is stored at room temperature for 1Y, 0.5C to 2.0V; and 0.5C, cycle 3 times, record the internal resistance, thickness and capacity before and after the core storage.

|

Normal |

Before storage at room temperature |

After constant temperature storage |

Calculate |

||||||||

|

Core |

Internal |

capacity |

Core thickness |

Internal |

First release |

Cycle tricapacity |

Expansion |

Internal resistance |

Capacity retention |

Capacity recovery |

|

|

4.41 |

2.89 |

1659 |

4.53 |

3.15 |

1476 |

1526 |

2.63 |

8.84 |

88.97 |

92.01 |

|

|

65°C |

Before high temperature storage |

After high |

Calculate |

||||||||

|

Core thickness / mm |

Internal |

capacity |

Core |

Internal |

First release |

Cycle |

Expansion |

Internal resistance |

Capacity retention |

Capacity recovery |

|

|

4.49 |

2.98 |

1649 |

4.70 |

3.12 |

1556 |

1609 |

4.59 |

4.74 |

94.35 |

97.58 |

|

|

80°C |

Before high temperature storage |

After high temperature storage |

Calculate |

||||||||

|

Core thickness / mm |

Internal resistance, |

capacity |

Core |

Internal |

First release |

Cycle |

Expansion |

Internal resistance |

Capacity |

Capacity |

|

|

4.47 |

2.91 |

1657 |

4.60 |

3.12 |

1600 |

1623 |

2.91 |

7.23 |

96.56 |

97.92 |

|

Why lithium iron phosphate (LiFePO4) batteries appropriate for commercial as well as commercial applications.

A couple of years in the energy field is generally considered a blink of an eye. This makes the quick improvement of the battery storage space market in recent years even more amazing. The battery storage space landscape in the electrical energy field is moving away from NiCd; it has actually changed in the direction of lithium-ion batteries, in addition to innovative lead-acid. For numerous applications, lithium-ion has confirmed better to other chemistries relative to energy and also power thickness, cycle and calendar life, and also price. The lithium-ion deep discharge cycle life, power and also power thickness, and also other features have shown preferable over various other battery types. Combined with quick cost reductions, this has actually caused boosted release of lithium-ion.

Lithium-ion is a group that includes lithium-titanate, lithium-iron phosphate, nickel-manganese-cobalt, lithium-manganese-spinel, nickel-cobalt-aluminum, lithium- cobalt. Because iron is one of the most secure component in the periodic table, lithium iron phosphate cells are likewise secure and risk-free. Lithium-iron-phosphate (LiFePO4) cells are typically accepted as the most effective lithium-ion type for industrial applications.

Lithium Iron Phosphate (LiFePO4) cells are typically accepted as the most effective lithium-ion battery for commercial applications.

LiFePO4 consist of practically no hazardous or unsafe products and are not typically thought about to be hazardous waste.

NiCd cells have cadmium, a recognized health hazard. Lead-acid batteries have lead, which can significantly influence psychological and also physical growth. Industrial NiCd batteries are categorized as harmful.

LiFePO4 are a safe technology that will not ignite or explode with overcharging, nor produce combustible gases under any kind of situations.

LiFePO4 consider one 3rd to one quarter of the weight of a lead-acid battery of equivalent power.

LiFePO4 can deliver greater than 5000 deep discharge cycles, contrasted to around 300 to 800 for ten-year design-life VRLA, or 1500 cycles to 50% depth of discharge for 20 year design-life VRLA.

In higher discharge-rate applications, LiFePO4 can generate dual the usable ability of in a similar way rated lead-acid batteries

LiFePO4 have a level voltage discharge curve, distribution little to no "voltage droop" (similar to lead-acid batteries).

LiFePO4 have a higher discharge-rate capability (10C continuous, 20C pulse discharge).

LiFePO4 approve higher continual cost prices - up to 3C, enabling much shorter reenergizing times, contrasted to VRLA which have 0.1 C to 0.25 C suggested fee prices.

Unlike lead-acid batteries, LiFePO4 can be left in a partially released state for extensive periods without triggering permanent decrease of capacity.

LiFePO4 can have reduced self-discharge prices (unlike lead-acid which will go flat quite rapidly if left sitting for extended periods).

LiFePO4 do not struggle with thermal runaway. SLA battery fee prices as well as obstruct temperatures should be restricted to avoid thermal runaway.

LiFePO4 can be utilized in high ambient temperature levels, as much as 65 oC without significant performance or service-life destruction. For every 10 oC increase in running temperature level, the service-life of a VRLA battery fifty percents.

LiFePO4 are relatively maintenance-free for the life of the battery. SLA batteries require yearly discharge ability testing, resistance or conductance screening.

LiFePO4 can be run in any positioning, including inverted. Numerous SLA batteries should be oriented vertically, some horizontally.

LiFePO4 do not have any type of hazardous heavy metals such as lead, cadmium, neither any type of harsh acid or antacid electrolyte.

LiFePO4 batteries are one of the most environmentally friendly battery chemistry available today.

LiFePO4 have practically two times the power density than NiCd.

LiFePO4 weigh about one 3rd to fifty percent of the weight of a NiCd battery of equivalent power.

LiFePO4 have fairly reduced self-discharge; less than half that of NiCd. Left uncharged, LiFePO4 cells can retain their fee for up to 10 years.

Higher cell voltage of LiFePO4 (3.6 V) indicates less cells as well as connected connections and electronics are required for high voltage batteries. One LiFePO4 cell can replace 3 NiCd cells, which have a cell voltage of only 1.2 V. (110V NiCd = 87 to 91 links, LiFePO4 will have 33 or 34 web links).

LiFePO4 include no liquid electrolyte which means they are immune from dripping. NiCd contain liquid potassium hydroxide which, if dripped, is very destructive therefore poisonous it is fatal if ingested.

In greater discharge rate applications LiFePO4 can create double the functional ability of in a similar way rated NiCd batteries.

Flat voltage discharge curve indicates optimal power available till completely released (no "voltage droop" just like NiCd batteries).

LiFePO4 cells can supply a very high discharge price, 10C constant, 20C pulse discharge.

LiFePO4 approve a lot greater charge prices - up to 3C = much faster reenergizing opportunities.

Unlike NiCd batteries, LiFePO4 can be left in a deep released st.